Projects

Current Projects

OMCS has an excellent reputation in working closely with customers on their specific materials needs. We are interested in collaborating with companies on individual short or long term projects, based around their areas of expertise and interest.

Green deal inspired correlative imaging-based characterization for safety profiling of 2D materials (ACCORDs)

ACCORDs will develop an imaging-based characterization framework (ACCORDs framework) for the holistic correlative assessment of Graphene Family Materials (GFMs) as a representative of 2D nanomaterials (NMs) to assess and predict 2D NMs health and environmental risks. The ACCORDs framework will operationalise safe and sustainable by design (SSbD) strategies proposed in past or ongoing H2020 projects or within OECD by correlating low-, medium-, and high-resolution physico-chemical-biological imaging based methods with non-imaging methods in a tiered approach. ACCORDs will deliver the ACCORDs framework and user guidance, new imaging-based characterisation methods (3-6 methods), reference in vitro tests (up to three new tests), new reference 2D NMs (up to three) for different matrices, a new minimum information reporting guideline for FAIR data sharing and reuse of images as well as an atlas with reference images for diagnostics of compromised safety of GFMs / GFM products. The new guidelines and standard proposals will be submitted to standardisation bodies to allow creation of regulatory ready products.

The novelty of ACCORDs is in translating the principles of medical imaging-based diagnostics to 2D material hazard diagnostics. ACCORDs will accelerate industrial sectors in the area of aviation, marine construction, drone production, flexible electronics, photovoltaics, photocatalytics and print inks-based sensors. The value ACCORDs proposes to the graphene industry are practical, easy, imaging-based tools for GFM quality monitoring next to the production line with a possibility to be correlated with advanced high-resolution imaging characterization methods in case hazard i.e. deviation from controls (benchmark values) are diagnosed. The ACCORDs framework and tools will contribute to the European Green Deal by addressing the topic: “Graphene: Europe in the lead” and to a new European strategy on standardization, released on 2nd February, 2022.

Undergraduate Part II project in collaboration with Leonardo MW Ltd

3D printed parts are now moving into production; however, there remains some concerns about the strength and durability of 3D printed parts, especially for the aerospace sector. This project aims to use dynamic mechanical analysis (DMA) to look at how fibre reinforcement improves the stiffness and strength of 3D printed polymer parts, in particular comparing the performance of printed Onxy (chopped fibre reinforced nylon) and continuous fibre reinforced Onxy against non-reinforced nylon. The stress/strain properties of the parts will be measured as a function of temperature and frequency, and the microstructure and distribution of the reinforcement will be investigated.

Past Projects

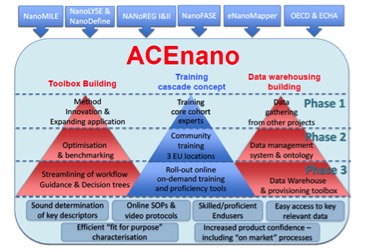

ACEnano will introduce confidence, adaptability and clarity into nanomaterial risk assessment by developing a widely implementable and robust tiered approach to nanomaterials physicochemical characterisation that will simplify and facilitate contextual (hazard or exposure) description and its transcription into a reliable nanomaterials grouping framework.

This will be achieved by the creation of a “conceptual toolbox” including a tiered approach to cost efficient nanomaterials analysis that will facilitate decision-making in choice of techniques and SOPs, linked to a characterisation ontology framework for grouping and risk assessment.

ACEnano will initiate activities to support data collection, management, interpretation and delivery to a data warehouse for safe use & storage. It will thus underpin the future of nanomaterial quality control, labelling and anti-counterfeiting.

OMCS is collaborating in a Nexeon lead project to optimise coating technology for its silicon anode material. This approach will result in improved cell performance, and also extend the system compatibility of silicon anode materials, allowing use of lower cost electrolyte formulations and lower overall battery cell costs.

The project, named Silicon Product Improvement through Coating Enhancement (SPICE), is underway, and is expected to take 24 months to complete. The focus of the work will be the use of an optimised coating for improved surface morphology, leading to improved conductivity of the underlying anode material for faster charge rates, and sustained capacity of the battery during charge / discharge cycles.

The consortium comprises Nexeon, Phoenix Scientific Industries (PSI), AMTE Power plc (formerly AGM Batteries Limited) and Oxford University’s Department of Materials (OMCS). The team has been awarded £2 million in funding through the Government’s ISCF Faraday Battery Challenge by Innovate UK, part of UK Research and Innovation, which is matched with a further £1.3m in funding from the industrial partners.

Battery cells typically represent >60% of the cost of an electric vehicle (EV) battery pack and almost 100% are currently imported to the UK. Security of supply is a major concern for UK pack builders and vehicle OEMs. The need for UK based core cell material manufacturers is partly addressed through this project - secure supply of IP rich, cell performance enhancing materials means that the cells developed in the UK can offer leading edge performance and provide the consortium members the confidence to scale beyond niche and into mass market application.

OMCS brings its expertise in analysing battery materials and the application of state-of-the-art characterisation techniques (high resolution transmission electron microscopy, focused ion beam milling, X-ray photoelectron spectroscopy, Raman spectroscopy) to help understand and optimise the carbon coating process. This includes assessing the surface chemistry, uniformity, quality and ultimately the performance of the enhanced anode material. In the latter stages of the project OMCS will also undertake full cell analysis and investigate end of life cells after accelerated and aggressive cycling.

Progress is needed in the prediction of environmental distribution, concentration and form (speciation) of nanomaterials, to allow early assessment of potential environmental and human exposure and risks, to facilitate safe product design and to include these aspects in nano regulation.

The overarching objective of NanoFASE is to deliver an Integrated Exposure Assessment Framework (protocols, models, parameter values, guidance ...) that:

- Allows all stakeholders to assess the environmental fate of nano releases from industrial nano-enabled products,

- Is acceptable in regulatory registrations and can be integrated into the EUSES model for REACH assessment,

- Allows industry a cost-effective product-to-market process, and

- Delivers the understanding at all levels to support dialogue with public and consumers.

The ambition is to reach a level of ENM Fate and exposure assessment at least comparable with that for conventional chemicals.

For that, NanoFASE will develop a set of novel concepts and approaches to underpin the Framework, developed as common themes linking the research, exploitation and dissemination throughout the project.

Our vision is to move from the current mainly mass-based lifecycle and release flow approaches towards systems that can account for spatial and temporal variability of ENM release, environmental transport and fate. The framework, supported by standard operating procedures (SOPs), parameter values, models and guidance, will incorporate:

1. the behaviour of the actual relevant ENM forms released from ENM products (a distribution of composite bound and free particles);

2. how reactions in waste management and environmental compartments (or "reactors") transform such release-relevant ENMs (integrating environmental speciation with ENM properties); and

3. the consequences of these transformations for transport and fate and among the different environmental compartments including organism uptake and local accumulation of ENMs in some environmental compartments ("environmental sinks" and hot spots).

The Advanced Lithium Ion Capacitors and Electrodes (ALICE) project will develop lithium ion capacitors (LICs) and validate these in a 48V module for use in three market sectors - automotive, e-bus and materials handling equipment.

LICs combine the benefits of lithium ion and supercapacitor electrode materials and structures, providing enhancing energy density vs supercapacitors and better power density than batteries.

Advanced materials will be developed and scaled (Johnson Matthey) and novel coating techniques (Oxford) used to provide electrode structures optimsed for high rate capability. Roll to roll coating and A5 pouch cell manufacture (Warwick Manufacturing Group) will be followed by 48V module build and testing (Johnson Matthey Battery Systems (JMBS)) based on end user defined requirements (Nacco Materials Handling, BAE systems, JMBS and Delta Motorsport) and accelerated test protocols. Development of a physics based cell model (Imperial) will interlink with sophisticated layer structure characterisation (tomography, TEM) & cell performance results, evolving a rational design approach for specific end use scenarios.

In PEICAP (Power Electronic Inverters & CAPacitors) Safran Power UK (lead partner) will work with Industrial Capacitors Wrexham Ltd and the University of Oxford to optimise the use of passive filtering and other components on aircraft electrical power systems.

Safran Power UK are a Tier 1 aerospace supplier, providing equipment and controls for aircraft power systems on a variety of civil platforms.

Industrial Capacitors Wrexham Ltd are a supplier of specialist capacitors.

The University of Oxford Materials Department is a globally recognised research centre in material science, especially in relation to electronic applications.

Programme FP7-NMP Project Reference: 255749

S. Godard-Desmarest, Dr. C. Johnston, Professor P.S. Grant.

Due to safety considerations, the aerospace industry is largely exempt from legislation prohibiting the use of lead in interconnects in electronic assemblies, and lead continues to be used in avionics. This situation is unlikely to continue because of further legislation and difficulties in sourcing lead-containing materials and assemblies from suppliers. In contrast to domestic electronics where lead free solders are now standard and reliable, there are no current widely accepted "drop-in" replacement materials for lead solders that meet the more stringent and hostile aerospace standards for reliability. There is now a pressing need to develop underpinning scientific understanding of the factors governing lifetime of existing and future lead free solder materials for critical aerospace applications. Previous work at Oxford has shown that nanoindentation can be used to measure the mechanical properties and constitutive behaviour of ball grid array solders as a function of temperature, and that with careful interpretation, this data can be used in simulations of stress-strain that in turn can be correlated to reliability performance. The significance of the approach is that unlike previous approaches that have relied on time-consuming and costly mechanical testing of bulk materials to obtain basic property data, the nanoindentation and modelling route offers the potential to identify more rapidly promising lead free alloys that meet aerospace requirements, usually quick methods and very small amounts of candidate materials. The project will build on the approach established at Oxford to study a variety of promising new lead free solder compositions for aerospace applications. Ball grid array joints are made in-house so that full process history data can be captured and reproducibility assured. These assemblies are probed by nanoindentation and the key mechanical behaviour (yield, temperature dependent creep, etc) captured and interpreted in a form suitable for input into a numerical model of stress-strain accumulation. In this way, the potential of alloys can be firstly ranked qualitatively, and then the most promising alloys studied in more detail by further probing and modelling, and thermal cycling or assemblies using equipment at Oxford and at industrial partners. This project is sponsored by EPSRC, Goodrich and Oxatech.

The NanoTOES project is a Marie Curie Initial Training Network focused on research to assess the health and environmental impacts of nanotechnology products. This research studentship is in collaboration with the Centre for Ecology and Hydrology, Wallingford Oxfordshire, and aims to determine toxicity for a range of metal and metal oxide based synthetic nanoparticles. The research will focus in particular on toxic effects on the biochemistry (gene expression, protein biology, cell biology) and behavioral and population ecology of the model nematode Caenorhabditis elegans.

The 6 main objectives of this project are:

1. Identify mechanisms by which nanomaterials induce cellular stress and immune activation.

2. Correlate size, shape, composition, coating of nanomaterials with defined cellular responses.

3. Distinguish cell-specific from general cellular responses for cells from selected tissues.

4. Identify the relevance of bystander substances and contaminants for nanotoxicity.

5. Analyse the influence of biological compounds and entities on engineered NP.

6. Develop and modify laboratory methods to allow their application in the work-place and in the environment.

Programme FP7-NMP Project Reference: 264506

There is a growing need to generate, convert and distribute electric power from the source to the load, which is fulfilled through the use of power electronics. Packaging and assembly of the power electronics modules is important in determining the efficiency, size, weight and manufacturing costs. The E2P project will seek to establish manufacturing methods to maximise thermal dissipation and minimise circuit parasitics through advanced interconnection and device embedding techniques and create a UK controlled supply chain for the manufacture of customised smart power modules.

Professor Chris Grovenor, Dr. Alison Crossley, Dr. Kerstin Jurkschat, Dr. Colin Johnston

Nanotechnology is a major growth industry which faces the risk of not realising its full economic and societal benefits due to public concerns over the safety of nanoparticles. Concerns are largely based around uncertainties about what the human and environmental costs of their use may be. NanoFATE is an EU FP VII funded multipartner collaborative project led by the UK Centre for Ecology and Hydrology. NanoFATE has been conceived to fill knowledge and methodological gaps currently impeding sound assessment of environmental risks posed by engineered nanoparticles (ENPs). Our vision is to assess environmental ENP fate and risk in for example high volume products for which recycling is not an option, namely; fuel additives, polishing agents, personal care products and antibacterial products. To represent these products commercial ENPs of CeO2 ,ZnO and Ag will be followed through their postproduction life cycles, i.e. from environmental entry as “spent product”, through waste treatment to their final fates and potential toxic effects. This will test the applicability of current fate and risk assessment methods and identify improvements required for assessment of ENPs at an early stage.

Programme FP7-NMP Project Reference: 247739